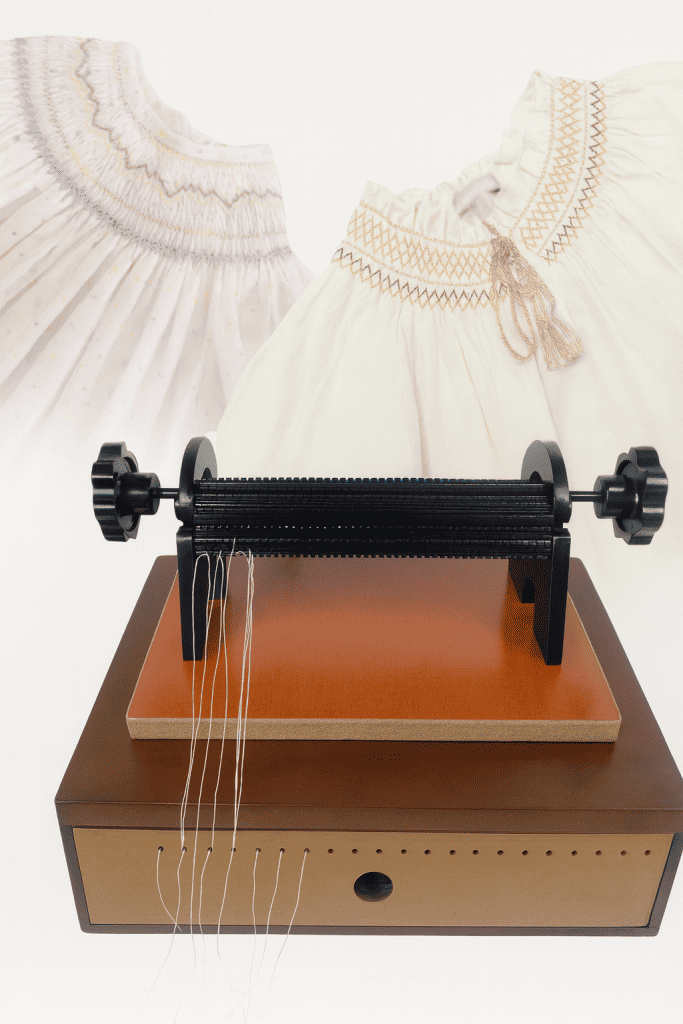

If you’ve ever admired the neat gathers on a handmade dress or the gentle texture on heirloom linens, you’ve already appreciated the art of smocking.

It’s a technique that gives fabric movement and character – classic, yet completely relevant for modern sewing.

Today, pleating machines make this once intricate process simple and reliable.

With just a turn of the handle, fabric feeds through and forms even pleats, ready for stitching or embroidery.

It’s a practical way to bring timeless texture into your projects, whether you sew for your home, your children, or your own wardrobe.

In this article, we’ll look at how smocking pleating machines work, what features matter most, and how to choose one that fits your sewing goals.

What a Smocking Pleating Machine Actually Does

A smocking pleating machine is a hand-cranked tool that gathers fabric into evenly spaced pleats – ready for smocking, embroidery, or decorative stitching.

It replaces hours of manual marking and gathering with a smooth, consistent process.

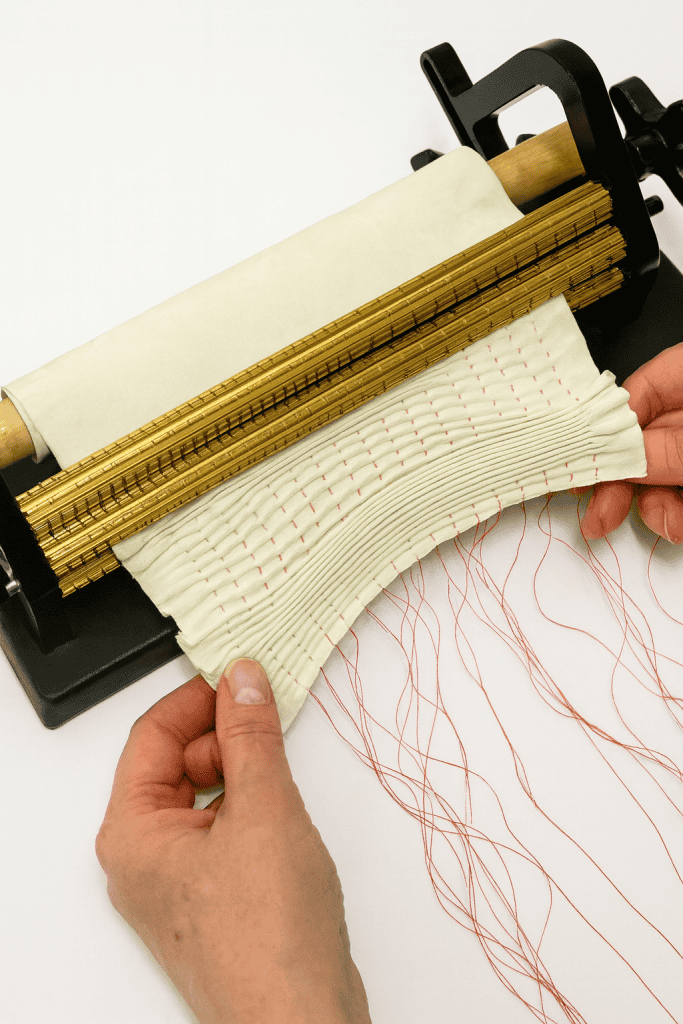

Here’s how it works in practice:

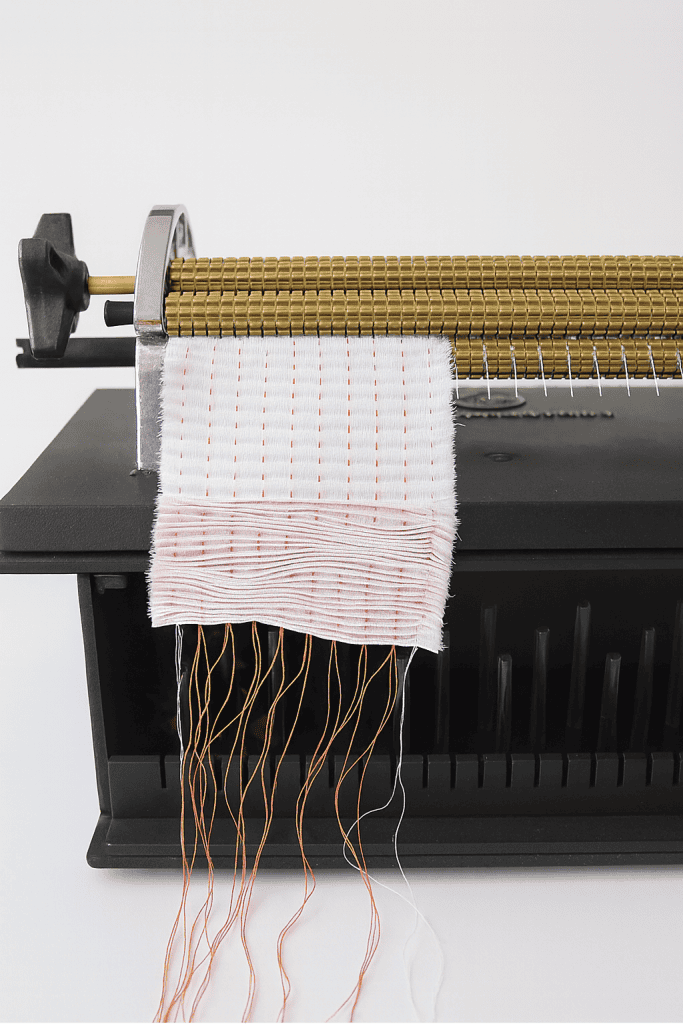

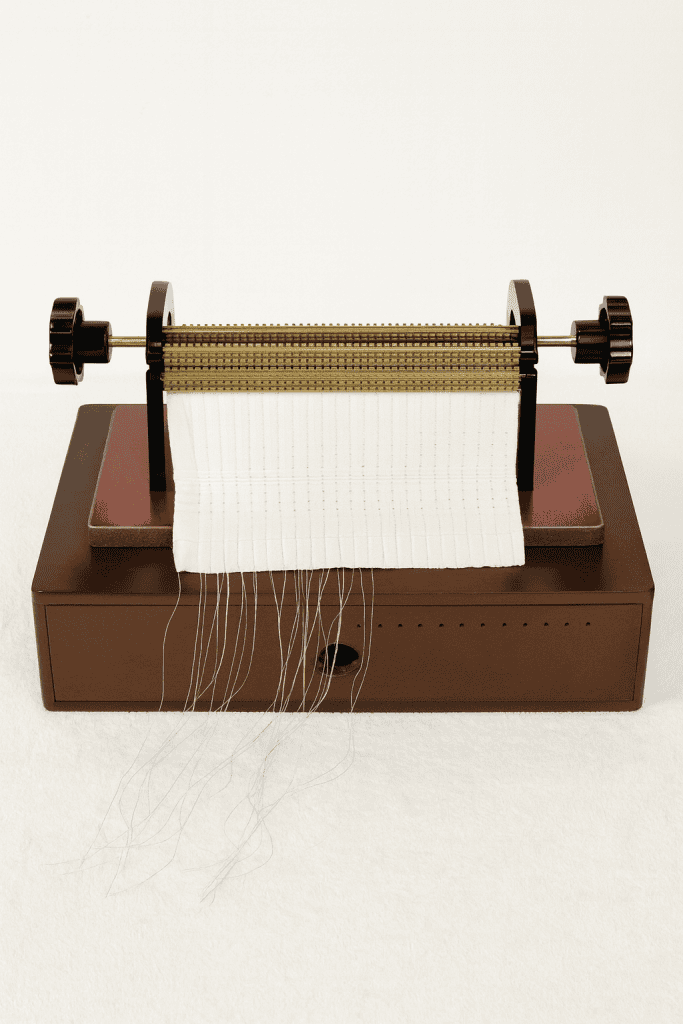

- Rollers and Needles: The machine has a set of grooved rollers fitted with multiple needles. As you turn the handle, the fabric feeds through, and each needle threads a row of gathering stitches.

- Uniform Pleats: When the fabric exits the rollers, it’s neatly pleated across the entire width – perfectly spaced and even from edge to edge.

- Fabric Compatibility: Lightweight woven fabrics work best. Cotton lawn, voile, batiste, and fine linen glide through smoothly and hold their pleats well. Thicker materials like canvas or denim are too heavy for the needles.

- Needle Count and Spacing: Most home pleaters have 16 to 32 needles spaced about ¼ inch apart. More needles mean you can pleat wider fabric sections or create denser designs.

- Thread Rows: Each needle holds its own thread, which becomes a row of gathers. You can use different thread colors or weights to mark design areas or add subtle visual structure.

Once the fabric is pleated, it’s ready for hand-stitching or embroidery.

The pleater simply ensures every gather is even, giving your handmade pieces a clean, professional foundation.

If you want a simpler option for projects like skirts, cuffs, or trim, you can also learn how to easily make gathers for beautiful ruffles, which works well when full smocking pleats are not needed but you still want soft, even fullness.

Key Features to Understand Before Buying

Before choosing a pleating machine, it helps to know which details actually affect how it performs.

While all pleaters serve the same purpose – turning flat fabric into even gathers – small differences in construction and design can change your results and your overall sewing experience.

1. Number of Rows (Needles)

Pleaters are usually described by how many needles they have – commonly 16, 24, or 32.

- 16-row pleaters are compact and ideal for smaller projects like baby clothes or narrow trims.

- 24-row pleaters are the most versatile for home sewing, giving you enough width for dresses or home décor panels.

- 32-row pleaters are for large, detailed smocking or professional use.

More needles mean a wider fabric section can be pleated at once, saving time when you work on bigger projects.

2. Needle Spacing

The spacing between needles – often ¼ inch (6 mm) or ⅜ inch (9 mm) – determines how close your pleats sit.

- Closer spacing (¼ inch) creates fine, delicate pleats suited for detailed smocking or lightweight fabrics.

- Wider spacing (⅜ inch) gives a softer, looser look that works beautifully on mid-weight fabrics or for a less dense design.

3. Fabric Compatibility

Pleaters handle lightweight woven fabrics best – cotton lawn, batiste, voile, or fine linen.

These fabrics glide through the rollers without stretching or jamming.

Avoid heavy, coated, or knit materials since they don’t feed evenly and may strain the needles.

4. Roller and Frame Quality

A well-built machine uses metal rollers and a sturdy steel or aluminum frame.

The rollers should turn smoothly with no slipping.

Wooden or plastic rollers can work for occasional use, but metal parts maintain even pressure and last longer with frequent sewing.

5. Ease of Use and Maintenance

A smooth hand crank, clear threading guides, and removable needles make a big difference when you use your pleater often.

Machines like the Read and Sally Stanley models let you replace individual needles instead of entire rows, which is convenient and cost-saving.

A light wipe after each use and occasional lubrication (following the manufacturer’s notes) will keep the rollers moving freely and prevent thread buildup.

If you are new to specialty tools, having a basic understanding of the anatomy of a sewing machine makes it easier to evaluate pleating machines too, since many of the same mechanical principles apply to rollers, needles, and tension control.

The Main Types of Smocking Pleating Machines

Pleating machines come in a few main categories, each built for a slightly different purpose.

The right one for you depends on how often you sew, the kind of fabric you prefer, and the size of your projects.

Understanding these types makes it easier to match the machine to your workflow instead of adjusting your sewing habits around the tool.

1. Compact or Beginner Pleaters

Compact pleaters, often 16 to 24 rows wide, are designed for ease and simplicity.

They’re lightweight, easy to store, and ideal for small garments, cuffs, collars, or doll clothes.

- Best for: Beginners or occasional sewists

- Common examples: Sally Stanley 24-row, Read 16-row

- Why it’s a good fit: They require less fabric handling and let you learn pleating technique without the weight or complexity of larger models.

2. Standard/Home Pleaters

The most popular option for home sewing, standard pleaters typically feature 24 to 32 rows.

They balance size, versatility, and stability, making them reliable for clothing, home décor, and children’s wear.

- Best for: Intermediate sewists or frequent hobbyists

- Common examples: Read 24-row, Amanda Jane 24-row

- Why it’s a good fit: The larger width and solid build let you pleat wider fabric sections while keeping the feed motion smooth and consistent.

3. Professional or Heirloom Pleaters

Professional pleaters are built for continuous, high-volume use.

They usually have heavy-duty metal frames, precision gears, and up to 32 rows.

These machines handle frequent pleating sessions without losing tension or alignment.

- Best for: Small business owners, heirloom sewists, or advanced makers

- Common examples: Read Maxi 32-row, Golden Hinde 32-row

- Why it’s a good fit: These models deliver long-term reliability and can manage fine fabrics with even tension – ideal for large smocking projects or production work.

4. Manual vs. Electric Pleaters

Most pleating machines are manual, operated by a smooth hand crank.

Some professional versions include a small motor for automated feeding, which keeps pleats uniform over long fabric lengths.

- Manual pleaters give you better control, especially for delicate fabrics.

- Electric pleaters save time on large, repetitive projects.

Choosing between them often comes down to your rhythm – whether you enjoy the hands-on process or want efficiency for larger production work.

Top 4 Smocking Pleating Machines

When you’re ready to choose a specific machine, here are four trusted models – each suiting a different level of sewing activity and budget.

All are viable picks; the “best” will depend on how you sew, how often, and what you make.

1. Read 24/47 Row Super Maxi Smocking Pleater

This is a mid-to-upper-range home model built for versatility.

It offers 24 full rows plus 23 half-spaces (for a total of 47 needle slots) across a 9 ” wide pleating width.

Why you might choose it:

- Wide enough to pleat generous panels (dresses, cushions) while still manageable in a home studio.

- Brass rollers and a heavy-duty, anti-skid base give a stable feed even when working with fine fabrics.

- Good for sewists who already have some pleating experience and want a reliable machine for frequent use.

Considerations:

- Larger footprint and cost higher than beginner models – worth it if you’ll use it regularly.

2. Princess 24 Row Smocking Pleater

This model comes from British craftsmanship with a strong reputation.

It features 24 rows with half-spacing options and roughly a 23.7 cm (≈9.3″) width roller.

Why you might choose it:

- Excellent build quality with solid brass rollers and aluminium side plates for long-term use.

- Ideal for sewists looking for a machine that can grow with their craft – whether for children’s wear, home décor, or small business use.

- Offers a professional feel without going to full industrial scale.

Considerations:

- Being export/import may mean higher shipping or customs costs depending on your region.

- The half-spacing feature gives extra flexibility but may require more attention to fabric feed.

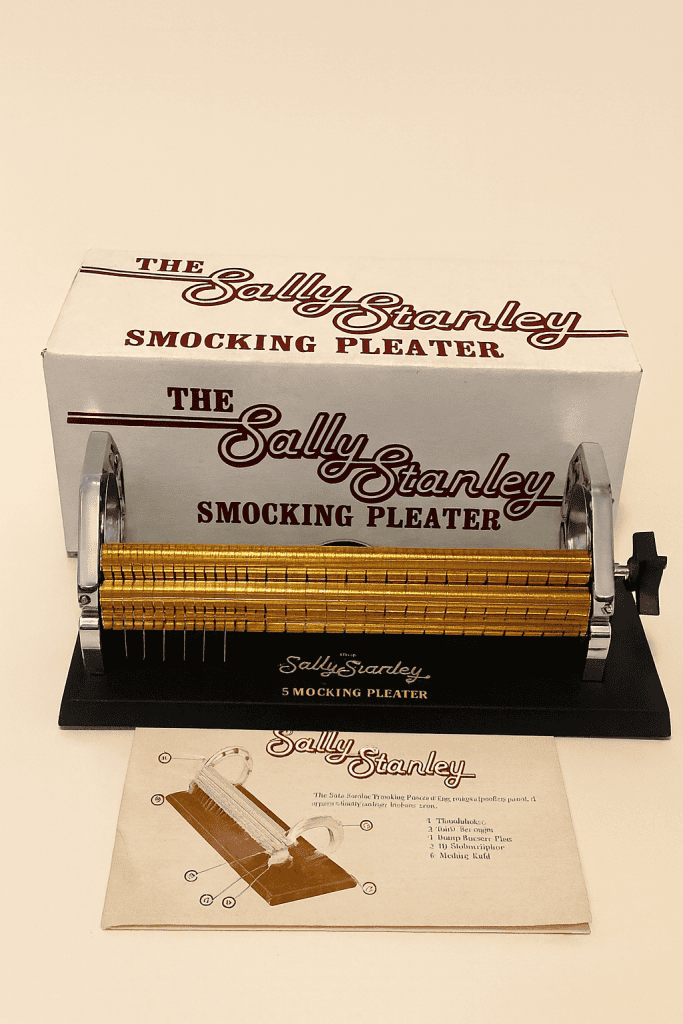

3. Sally Stanley 24 Row Smocking Pleater

A well-established classic among home pleating machines.

According to a retailer, the Sally Stanley pleater “works very smoothly and makes perfect pleats.”

Why you might choose it:

- Straightforward to use – good fit if you’re building pleating skills.

- Genuine parts and accessories available (needles, instruction manuals) make maintenance easier.

- Strong value for money for regular hobby use.

Considerations:

- Slightly fewer extra features (roller width, row count) compared to the premium models.

- If you plan to pleat very wide fabrics or do business-level production, a larger machine may serve better.

4. Generic 24 Row Smocking Pleater (0.2‑9.4 inch width)

This is more of a budget/entry-level option (from a generic brand) and may suit sewists just starting or experimenting.

For example, one listing describes a 24-row pleater adjustable from 0.2–9.4 in width.

Why you might choose it:

- Lower cost entry point to pleating without large investment.

- If your projects are smaller (trim, children’s clothes, sampling) you may not need the premium build.

- Good for learning the process of pleating and smocking without the pressure of a more expensive machine.

Considerations:

- Build materials and precision may not match the premium brands – roller smoothness, long-term durability, accessory support might be less robust.

- Fewer reviews; for heavier or frequent use the premium machines may outlast this one.

How to Choose the One That’s Right for You

The best smocking pleating machine is the one that fits your projects, pace, and workspace.

Before you buy, think about what you sew most often and how you like to work.

A few key considerations will help narrow the options with confidence.

1. Match the Machine to Your Project Scale

If your projects are small – like baby dresses, cuffs, or trim – a compact 16- or 24-row pleater will serve you well.

For larger garments, curtains, or production work, a 32-row or “Super Maxi” model gives more room to pleat wide panels efficiently.

Tip: The wider the roller, the less often you’ll need to re-feed fabric mid-project.

2. Consider How Often You Sew

Your level of use should guide your investment.

- Occasional use: A basic home model like the Sally Stanley 24-Row is simple, dependable, and easy to maintain.

- Frequent use: Mid-range pleaters such as the Princess or Amanda Jane handle consistent sewing sessions without strain.

- Professional or high-volume use: The Read Super Maxi or similar heavy-duty models are built for daily work and long-term precision.

3. Choose the Fabric Range You’ll Work With

Not all fabrics behave the same. Lightweight cottons, voile, batiste, and linen feed best through pleaters.

If your projects lean toward heavier fabrics, pick a machine with stronger rollers and a smooth, well-aligned crank mechanism to maintain even tension.

4. Look for Support and Replacement Parts

A pleating machine is a long-term tool.

Choose a brand that offers replacement needles and clear maintenance guidance.

Readily available parts make upkeep easier and extend your machine’s lifespan.

5. Think About Comfort and Workflow

A machine should fit your workspace and rhythm.

Consider whether you prefer a manual crank – offering tactile control – or a motorized pleater that handles longer runs automatically.

The goal is to choose what keeps your process steady and enjoyable.

6. Value Over Price

Pleating machines aren’t impulse buys; they’re investments in precision.

A reliable, well-built pleater costs more upfront but saves frustration and replacement costs later.

Choose the best one your budget comfortably allows, focusing on performance rather than extras you won’t use.

Bottom Line

The right machine is the one that supports how you sew most often – not necessarily the biggest or most expensive.

Choose the model that fits your fabric, frequency, and workspace, and it will serve you well for years of confident, beautifully pleated sewing.

If you also work with overlocking and finishing seams, understanding the anatomy of a serger can help you decide how a pleating machine fits into your overall sewing setup and workflow.

How to Maintain Your Smocking Pleater for Long-Term Use

A well-kept pleating machine stays accurate and smooth for decades.

Basic care takes only a few minutes after each sewing session and prevents fabric snags or roller strain.

1. Clean After Every Use

- Brush away lint and stray threads from the rollers, needles, and feed slots.

- Use a soft, dry cloth (never water or solvent) to wipe the rollers clean.

- If you pleat fine cotton or voile, a small artist’s brush works well to remove thread bits between grooves.

2. Check the Needles Regularly

- Inspect needles for bends or dull tips every few projects.

- Replace any that resist threading or leave uneven gathers; most brands sell individual replacement packs.

- Store extra needles in a labeled container to avoid mixing sizes.

3. Keep Rollers Turning Smoothly

- Once every few months, apply a drop of light sewing-machine oil to the roller shafts (if recommended by the manufacturer).

- Turn the crank slowly a few times to distribute the oil evenly, then wipe away any excess.

- Never over-lubricate – the goal is a thin, invisible layer to keep motion steady.

4. Store Properly

- Cover the pleater when not in use to protect it from dust and humidity.

- Store it flat, with the handle secured, in a dry area away from direct sunlight or heat.

- Avoid stacking heavy objects on top; this prevents frame warping or roller misalignment.

5. Annual Maintenance Check

Once a year, give your machine a quick tune-up: remove all needles, clean the channels thoroughly, and inspect gears or tension screws.

A careful look once a year keeps the rollers aligned and ready for long-term accuracy.

If you’re getting started with sewing, check out this step-by-step guide on how to set up your sewing machine to get smooth, even stitches from the very first project.

Choose the Pleating Machine That Matches How You Sew

The best pleating machine is the one that fits comfortably into your sewing rhythm.

Think about what you create most often, how much space you have, and the kind of fabric you love working with.

When your machine matches your pace and purpose, smocking becomes effortless and enjoyable.

Whether you’re sewing heirloom dresses, home décor, or learning the craft for the first time, a good pleater will make your work smoother, cleaner, and more consistent.

Which pleating machine are you considering – or already using? Share your experience or questions in the comments below.

Your insight might help another sewist find their perfect match!

FAQs

1. Can I pleat knit fabrics with a smocking pleater?

Not usually. Smocking pleaters are designed for lightweight woven fabrics like cotton lawn, voile, or fine linen.

Knits stretch and can snag in the rollers, causing uneven pleats.

If you want to pleat knit fabric, use hand-gathering or elastic-thread techniques instead.

2. How wide of a fabric piece can I pleat at once?

It depends on your pleater’s row count and roller width.

- A 24-row pleater usually handles about 9 inches (23 cm) of fabric per pass.

- A 32-row pleater can pleat around 12 inches (30 cm) at once.

You can always re-feed additional sections if your fabric is wider – just align the pleats carefully.

3. How many threads do I need to load into the machine?

Load one thread per needle. For a 24-row pleater, that means 24 separate threads.

Most sewists use cotton or polyester thread in contrasting color to their fabric so the pleats are easy to see during stitching.

4. Do pleating machines need special needles or thread?

Yes. Use pleater-specific needles sold by the same brand as your machine; they differ slightly in length and hook shape.

Standard sewing machine needles don’t fit. For thread, choose a strong, smooth thread (like cotton-wrapped polyester) that won’t snap when you pull gathers.

5. How do I fix pleats that came out uneven?

If pleats feed unevenly, check these points:

- Fabric should be lightly starched and cut straight on the grain.

- The rollers must be lint-free so the fabric doesn’t drag.

- Feed the fabric with steady, even tension – don’t pull or push.

If a few pleats are off, you can re-thread that section or lightly re-pleat by hand before stitching.